One of the most important achievements of personal computers and mobile wireless technologies is that they have made it possible for the general public to do things that could previously be done only by professionals.

Take video for example: according to YouTube statistics, 300 hours of digital video is uploaded every minute of every day by people all over the world. This remarkable volume of video is being generated because just about anyone can record, edit and upload a high-definition movie from their smartphone. According to a recent Pew Research study, about one third of online adults (ages 18-50) had posted digital video to a website by 2013.

It is easy to take for granted the video production functions that are performed routinely today on inexpensive and easy to use mobile devices. Less than ten years ago, the ability to capture and edit HD video would have cost tens of thousands of dollars in digital camera and production equipment and required extensive training to use it.

The same can be said for the ability to quickly create a document in a word processing program and insert high resolution graphics anywhere on the page, cropping and scaling as needed. Applying filters and adjusting image quality (contrast, brightness, sharpness) is also second nature as these functions are today available on every mobile device.

CEPS

Four decades ago, before the personal computer existed, electronic image editing, scaling and cropping could only be performed on very expensive prepress systems that cost more than $1 million. That was during the era of what was known as color electronic prepress systems (CEPS) that were built on state-of-the-art minicomputers with reel-to-reel magnetic tape for data storage.

During the 1960s and 1970s, as commercial offset lithography and film-based color reproduction were overtaking letterpress and single color work, high-end digital electronic production systems were acquired by the big printing companies and major publishers that could afford the investment.

By the 1960s—after analog electronic systems had been widely adopted in pressrooms and prepress and typesetting departments across both Europe and America—a race was on to develop a fully computerized page composing system. Companies like Hell, Crosfield, Dai Nippon Screen and other companies that had been part of the post-war electronics revolution jumped into the market to try and solve the problem of merging text and color photographs together electronically on a computer display.

However, it was a newcomer to the graphic arts industry from Israel called Scitex, founded by Efraim “Efi” Arazi in 1968, that made the highly anticipated breakthrough. Foreshadowing the impact of PC-based desktop publishing on graphic communications in the late 1980s, Scitex introduced digital files and computerization to the prepress production process and forever changed the printing industry.

Scitex

Efi Arazi (born in Jerusalem on April 14, 1937) entered the Israeli military when he was 16 and without graduating from high school. He made a name for himself as an exceptional electronics specialist while working on radar systems in the Israeli air force. Following his military service, with the assistance of the US embassy Arazi was admitted to the Massachusetts Institute of Technology in 1958 as an “extraordinary case” despite his lack of the normally requisite secondary school diploma.

While attending MIT, Arazi also worked at Harvard University’s observatory and digital photography lab. Under the direction of Harvard Professor Mario Grossi, Arazi petitioned NASA and was awarded funds to develop a camera system for scanning the surface of the moon on the unmanned lunar probes in 1966 and 1967. It has also been reported that Arazi’s invention was part of the equipment on the Apollo 11 mission that captured and transmitted video of Neil Armstrong’s first footsteps on the Moon on July 20, 1969.

After earning a bachelor degree in engineering at MIT, Arazi worked in the US for a short time for Itek corporation, a US defense contractor that specialized in spy satellite imagery. In 1967 he returned to Israel and one year later—along with several others who had been educated in the US—founded Scientific Technologies (later shortened to Scitex) with the aim of developing electro-optical devices for commercial purposes.

Scitex’s first products were developed for the textile industry. The company sold nearly one hundred electronic systems that automated the process of creating knitting patterns. Since many colors were used in complex fabric designs such as the popular Jacquard pattern, Arazi and his Scitex team developed a scanner (Chroma-Scan) and image manipulation workstation (Response 80) that programmed electronic double-knit stitching looms.

These optical systems replaced manual and time consuming stitch-by-stitch drawings and punch cards that had been widely used in the textile industry up to that time. Scitex also later devised a system for imaging film for printing on textiles that included overprinting, trapping and repeating patterns.

Response 300

Recognizing the potential for new technologies in the growing international printing and publishing industries, Scitex began development in 1975 of a computerized color prepress system. Arazi stunned the graphic arts industry in the Fall of 1979 when he demonstrated the Response 300 system for the first time at the GEC expo in Milan, Italy.

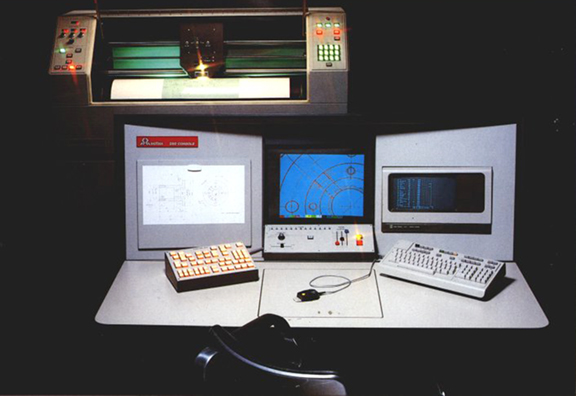

Response 300 included an integrated color drum scanner, image editing workstation and laser film plotter. Directly challenging the domination of high tech graphic arts equipment by Hell (Germany) and Crosfield (UK), Scitex was the first company in the world to combine color image retouching and page makeup onto a single console.

Prior to the Response 300, the electronic color scanning process was based on an analog transfer of color separation information directly from a drum scanner to the film output device. The innovation of Arazi and Scitex was to place a minicomputer (at that time an HP1000) between the scanner and plotter such that the color separations were captured and stored in digital form. The proprietary image files could then be color corrected, retouched, scaled and cropped on screen prior to final output as film separations.

In describing the significance of the accomplishment, industry historian Andy Tribute later explained, “It allowed you to do in real-time on a terminal the sort of things we do in Photoshop now. … I remember watching Efi do a demo where he had a picture of a person with a Rolex watch on and he changed the date in real time on the Rolex. Today that may seem nothing but back then it blew my mind”

Within one year, Scitex had sold $100 million of the Response systems to printers and publishers. Through the mid-1980s, Arazi led Scitex as it developed a suite of products (Raystar, SmartScanner, Whipser, Prisma and Prismax Superstation to name a few) that brought the latest in minicomputer technologies to high-end prepress workflows. Scitex customers gladly paid the $1 million price tag for the flexibility and time savings that Scitex provided.

DTP & EFI

Scitex remained an innovator throughout the 1980s and 1990s as proprietary technologies and CEPS gave way to desktop publishing, industry standard file formats and PostScript workflows. Scitex was among the first prepress technology companies to embrace the introduction of Macintosh computers into graphic arts production.

In 1988, Scitex partnered with Quark technologies—developer of the most sophisticated desktop publishing software at the time—and made it possible for QuarkXPress users to build compound documents with high resolution full color images to be output for both commercial and publication printing.

In 1985, Arazi pushed the industry forward with the development of Handshake, a Scitex product that allowed a wide variety of systems including those of competitors to send and receive data from the Response line of products. Later Scitex was an advocate of Digital Data Exchange Standards along with Hell, Crosfield, Eikonix and others to smooth that transfer of data between all systems in the industry.

In June 1988, Arazi stepped down as President and CEO of Scitex. Six months later, when Mirror Group’s Robert Maxwell acquired a controlling stake in Scitex, Efi Arazi also resigned as chairman of the board. While the company had reached the height of its success with revenues approaching $1 billion and 4,000 employees, Arazi knew that personal computers were transforming the industry and it was time to move on to other business ventures.

After Arazi’s departure, Scitex continued to develop prepress workflow systems, laser imaging equipment, desktop scanners, digital color and soft proofing devices. The company participated in the transition from film-based workflows to the direct-to-plate revolution of the mid-1990s.

Along with all of its competitors, Scitex began to struggle financially and ended up selling its graphic arts group to Vancouver-based competitor Creo Products in 2000. The division of the company that went into digital printing called Scitex Vision was acquired along with the Scitex name by HP in 2005. The remainder of the business was renamed Scailex at that time.

In 1988 Efi Arazi founded Electronics for Imaging (EFI) at the age of 51. The new venture was no less successful then Scitex as EFI raster image processors were integrated in many high quality color laser and toner based printing devices. The EFI Fiery technology quickly became a standard in the graphic arts industry by the 1990s for low cost, high quality color proofs. The company—which bears the first name of its founder as an acronym—later expanded into ink jet printing devices, printing industry productivity software and print server and workflow software tools. Today EFI is one of the most important and successful technology companies in the rapidly changing printing industry. Efraim Arazi died on April 14, 2013 at age 76.