Industry experts say that there are more than twenty thousand uses of paper in the world today. Communication, currency, hygiene, manufacturing, packaging and construction are a few of the commercial applications of paper. Remarkably, even with the growth of electronic and digital alternatives, the worldwide production of paper and cardboard has continued to expand.

Paper is so ubiquitous in our lives that it would seem that the subject of its origins and development would be of interest to just about everyone. Yet the versatility and utility of paper are such that we barely notice it. As librarian and historian John Bidwell has said, “If you’re noticing paper, that probably means there’s something wrong with it.”

Throughout its history, paper has served as the vehicle upon which an image is presented; it is the medium that delivers the message. The more invisible its “negative” form, the more effective paper carries its “positive” content.

Perhaps this background role is at least partially responsible for the perception that paper is more effect than cause; that the development of paper has always been driven by the requirements of what is printed upon it. However, the truth is that the evolution of paper and the methods of its making have proceeded in reciprocal relation to print, as both its catalyst and consequence.

* * * * *

And so it was that paper was invented by Ts’ai Lun (Cai Lun) in China in 105 AD initially for the purpose of facilitating calligraphy. By the time Oriental wood block printing was developed a century later, the making of hand writing papers was an established craft. The new printing method was adapted to the lightweight Chinese stock and the soft impression of the wood block prints could only be effectively made upon one side of this paper.

More than one thousand years later—after papermaking made its way across Asia and the Middle East and became established in Europe—a different kind of paper was being made. Crafted from macerated linen and cloth fibers, dipped in animal gelatin and dried to accommodate the quill pen, this paper was used by Gutenberg in the application of his movable metal printing types. The pressure of the inked metal type impression took to these hardened European papers in a manner that facilitated printing on both sides of the sheet.

Four-and-a-half centuries later, as print was being transformed from a craft to an industry, paper once again emerged as the driver of innovation. Many years before the application of metal construction, cylinders and steam power to printing machines, the technology of papermaking had undergone its own revolution.

The papermaking machine

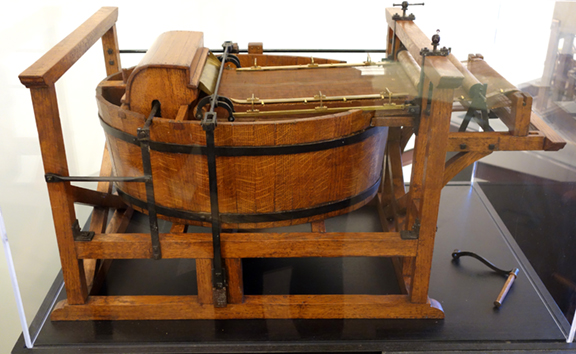

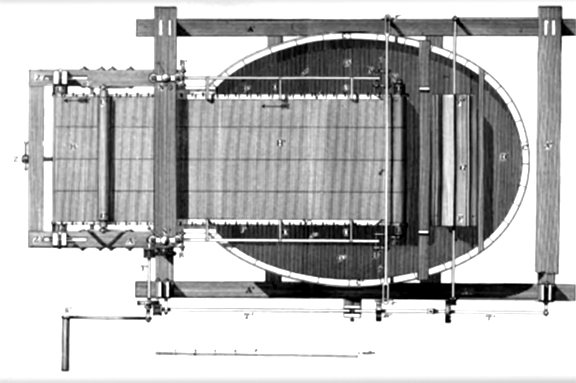

In 1798, Frenchman Nicholas-Louis Robert began the industrialization of printing by inventing the papermaking machine. Although there were many technical hurdles to be overcome, the essential features of Robert’s first successful invention have remained standard in paper manufacturing to this day.

Robert’s technical innovation was the rotating cloth screen (wire) belt that received a continuous flow of fibers and delivered an unbroken sheet of wet paper to a pair of squeeze rollers. As the long strip of paper came off the machine, in Robert’s configuration it was hung by hand to dry on a series of bars or cables. This would later become a roll of paper.

Prior to the Robert’s invention, all paper was made by hand and consisted of dipping a framed mould with a porous surface into a vat of fibers suspended in water. Upon lifting the mould from the vat, a thin layer of fibers rested on top of the screen and was dried to form a sheet of paper. With this method, the mould could be used again only when the sheet had dried and been removed from it.

Aside from its important technical features, the key results of the papermaking machine were:

- Productivity:

The volume of paper that previously would have taken many hand papermakers and many hours could be produced by a single operator in far less time. - Paper Size:

Sheet dimension was limited with handmade paper. It was not possible for a craftsman to adequately balance a large mould. With Robert’s machine, paper size was limited only by the width of the machine and the length was endless.

Nicholas-Louis Robert

Nicholas-Louis Robert was born in Paris in a small house on December 2, 1761. He had health problems as a child and was quite frail. Despite his condition, when he turned fifteen, the boy made an effort to join the French army because he was concerned that his aging parents could not afford to take care of him. The military did not allow him to join and Nicholas-Louis was returned to his parents’ home to continue his studies.

Four years later, following a period of severe mental anguish for having been a burden to the family, Nicholas-Louis again applied for military service. On April 23, 1780, he was admitted to the First Battalion of the Grenoble Artillery and was stationed in a garrison at Calais, a port city in Northern France across the English Channel from the clifftop town of Dover.

Robert’s military experience took a dramatic turn in 1781 when the young soldier was sent to war in the Caribbean during the American Revolution. The French Metz Artillery regiment sailed to Santo Domingo to fight an engagement against the British. Having won the battle, Nicholas-Louis returned home and shortly thereafter left the military at age 28 to seek an occupation in civilian life.

With a mechanical aptitude, Robert turned to the printing craft and landed a clerkship with the well-known printing, type founding and publishing company Didot in Paris. After working for several years in the office, Nicholas-Louis sought a new opportunity in related industries and came upon the paper mill operations of Francois Didot in Essones, a well-known papermaking center south of Paris.

The Didot papermaking operation was quite important as much of French paper currency was printed there. Nicholas-Louis initially obtained a position as mill personnel inspector. Having regular contact with the staff, Nicholas-Louis found that there many antagonisms among the hand paper making tradesmen and these problems frustrated him.

The invention

After working in the mill for months, it occurred to Robert that there was a more advanced method for making paper; that it might be possible to get around the constant quarrelling among the papermaking trades. While the discord among the employees of the mill may have been the impulse for Robert’s research—he was after all under the direction of the owner Didot—the fact is that his project led to a significant reduction in the cost and a more abundant supply of paper.

Robert’s initial attempts at a papermaking machine were failures and termed “feeble” by Didot. Nonetheless, Didot encouraged Nicholas-Louis to continue with his work. For a time, the young man gave up on his project and became involved in other areas of mill operations. But under the constant prodding of his boss, he returned to his research in mechanical papermaking.

Soon, with the help of others at the Didot establishment, Robert saw that the basic principles of his original concept were sound. His earlier work was revived and he proceeded with the construction of a device that was larger than the first machine. Finally, when trial sheets of paper had been effectively produced on the new machine, Didot encouraged Nicholas-Robert to file a patent for his invention.

On September 9, 1798, Robert and Didot traveled to Paris and presented a patent application to the French Minister of the Interior. In a letter that accompanied the application, Nicholas-Louis wrote, “It has been my dream to simplify the operation of making paper by forming it with infinite less expense, and, above all, in making sheets of an extraordinary length without the help of any worker, using only mechanical means. … The machine makes for economy of time and expense and extraordinary paper, being 12 to 15 meters (472 to 590 inches) in length, if one wishes.”

The patent was granted at a cost of 1,562 francs and dated January 18, 1799. Considering the fact that the maximum length of handmade paper was about 32 inches, Robert’s machine represented an enormous step forward. The French government recognized the significance of his invention and dispatched an engineer to the Didot mill to assist in the construction of an improved model.

The Bureau of Arts and Trades wrote of it, “this machine forms paper of great width and indefinite length. The machine makes paper of perfect quality in thickness and gives advantages that cannot be derived from ordinary methods of forming paper by hand, where each sheet is limited in size in comparison with those made on this machine.”

Further developments

Mention must be made of the fact that Robert’s papermaking machine was invented during the tumultuous years of the French Revolution (1789-1799). It is no accident that this technical breakthrough coincided with the spread of the ideas of “liberty, equality and fraternity” that depended greatly upon the printed word.

However, as the historian Dard Hunter described, the “disturbed conditions” of the period were such that very little progress was made by Didot and Robert beyond the initial invention. As Robert became preoccupied with the financial benefits of his accomplishment, he sold his patent to Didot for 25,000 francs, a modest sum considering the implications of the invention.

Didot immediately sought to move further development of the project out of France and into the more stable environment of England. Didot’s brother in law, John Gamble, was an English paper-mill owner and the two corresponded to have a much larger machine constructed. It was then that the London stationers Henry and Sealy Fourdrinier became involved in building papermaking machines.

Following several modifications to the wire, the Fourdrinier brothers invested 60,000 pounds in the construction of a large machine that could make paper on continuous rolls. This attempt was eventually proven successful and they were granted an English patent for it in 1806. However, the project was not commercially successful and it bankrupted the Fourdriniers. Nevertheless, to this day—although its basic design was invented by Nicholas-Louis Robert—the papermaking machine bears the Fourdrinier name.

While the Fourdrinier machine underwent rapid development in the nineteenth century, the ingenious Nicholas Louis was living quietly in France. When the first commercial papermaking machine was installed there in France in 1811, Robert was approaching fifty years of age and on his way out of the papermaking business. In 1812, he opened a small primary school in Vernouillet, northwest of Paris where he worked as a poorly paid teacher. Never realizing the financial benefit from his invention, Nicholas-Louis died broken and destitute on August 8, 1828. A monument to Robert’s memory was erected in 1912 outside the church at Vernouillet.